News Release

Closing the Loop on Computer-Aided Design & Manufacturing

San Diego, Calif., April 9, 2014 -- It seems a bit like a choose-your-own adventure story: You use computer-aided design to create a wind turbine. For 10 years you operate your turbine successfully but then disaster strikes in the form of a 6.8 (moment magnitude scale) earthquake. The decision is yours: Do you have confidence the turbine can continue to be safely operated, or do you decommission it, take your money and run?

|

(Oh, and don’t forget the hypothetical energy company that might sue you based on pre-established contractual language.)

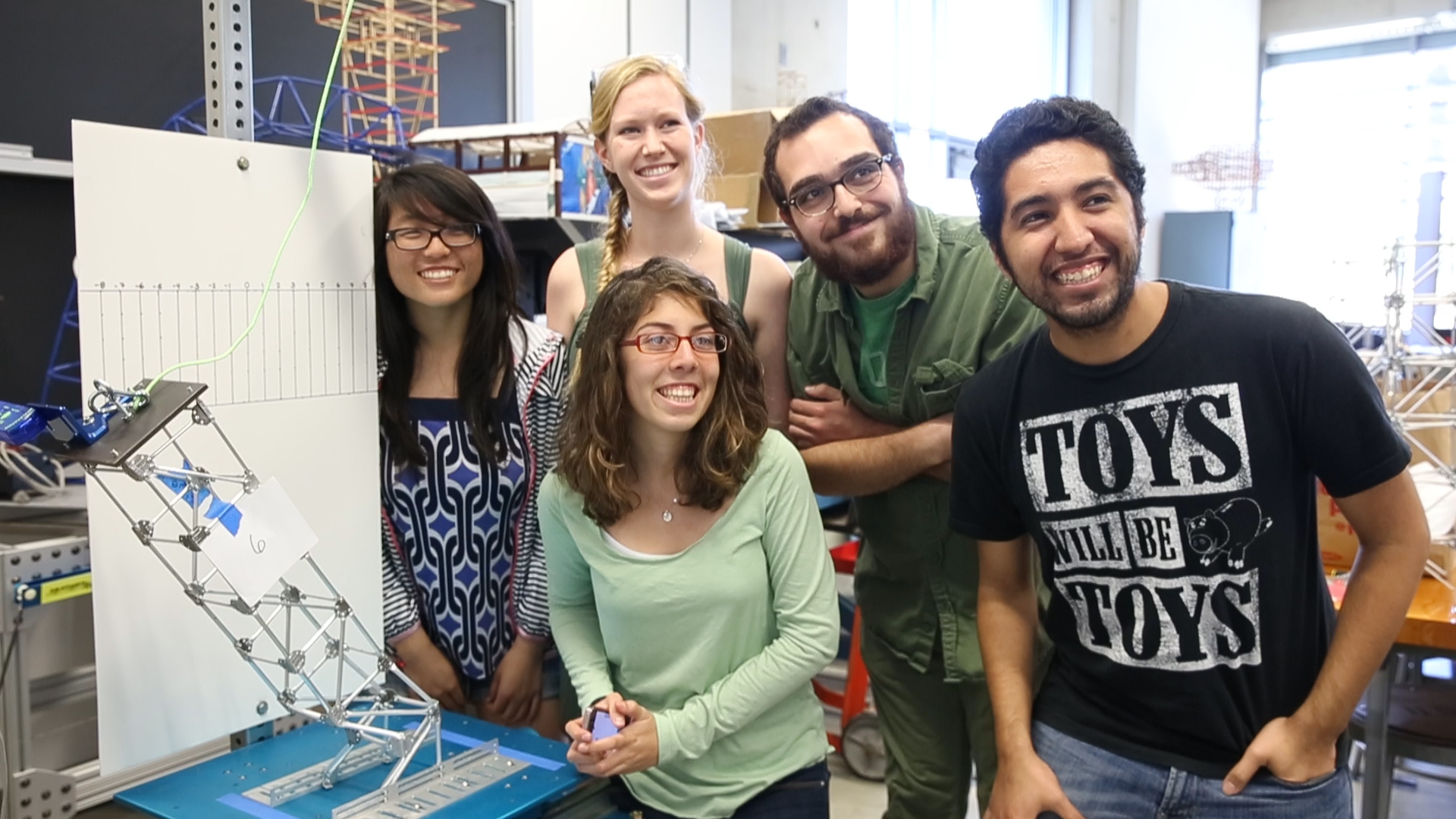

For undergraduates in the University of California, San Diego’s Structural Engineering 120 course, this fictional scenario became the focus of a very real classroom experiment this quarter in computer-aided design (CAD) and computer-aided manufacturing (CAM). Students were required to design, model, simulate, analyze and prototype a wind turbine — and this year, for the first time in the six years since the class has been offered, they were able to print 3D models of their turbine blades virtually overnight using Makerbot 3D printers.

“Normally, the challenge in designing structures is there’s a disconnect between the CAD world, the digital world and the physical world,” explains SE 120 instructor Falko Kuester, a professor of structural engineering and an affiliate of the Â鶹´«Ã½ Qualcomm Institute. “In this course, we model a structure using CAD techniques and run simulations to determine how that structural specimen performs under certain conditions. Usually that’s where instruction would stop, but our students actually build physical prototypes of the models they have designed with the CAD tools.

“In this way, rather than concentrating on just a particular tool or one step in the process, we expose them to the fundamental skills it takes to be creative,” he explains. “We design, simulate, prototype and test under life-like conditions and use lessons learned to inform the next design cycle. As the instructor, I provide background information and the engineering foundation to ask the right questions and not blindly trust design. We like to think of it as a closed-loop approach.”

|

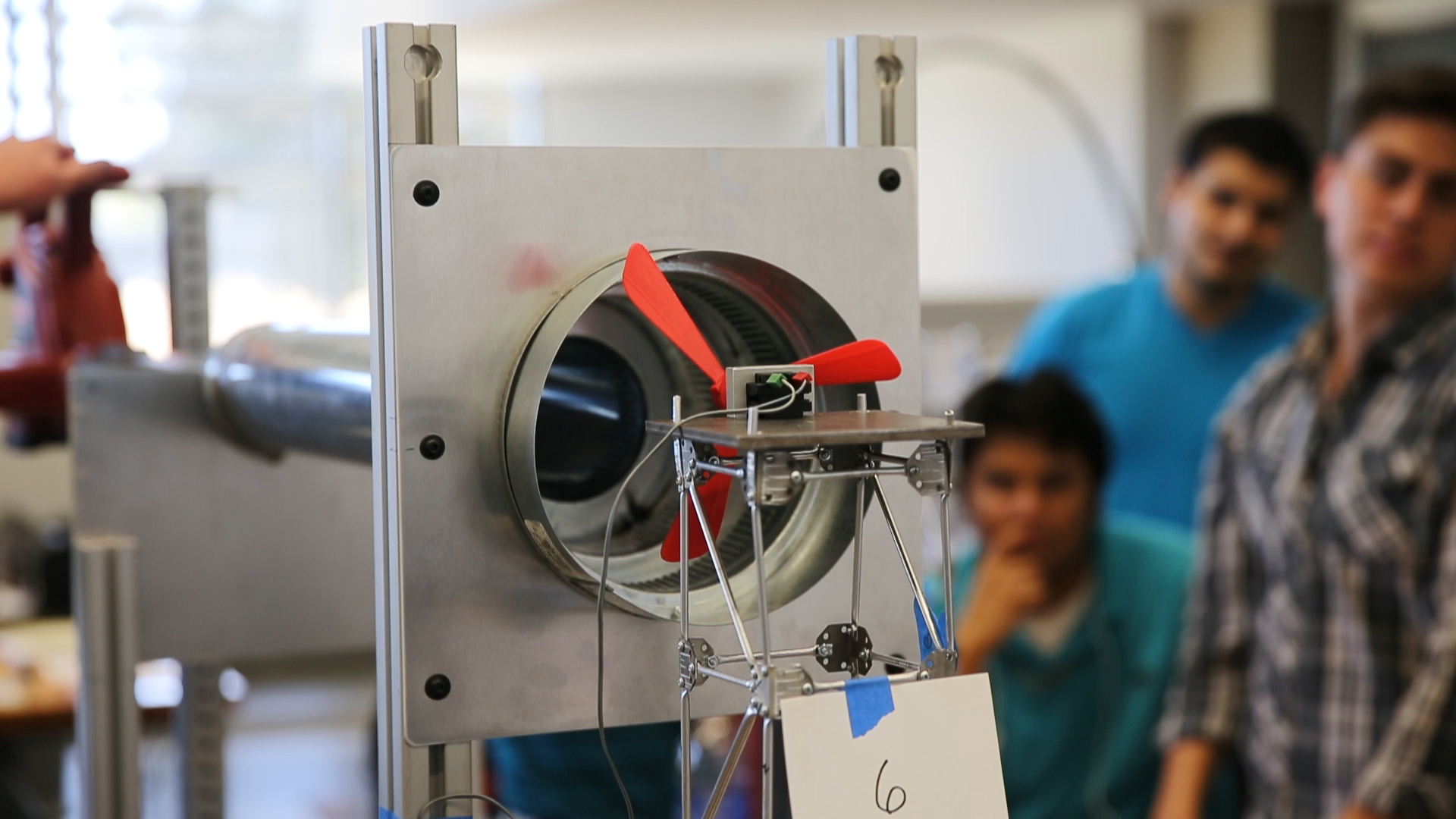

Prof. Kuester in collaboration with Senior Development Engineer Steve Porter, purposely designed the course to be as realistic an experience as possible. After student teams have created and verified their computer-aided designs, the teams submit them for rapid manufacturing (3D printing) and subsequent physical testing, which tells them if their designs can be manufactured, hold up under real-life conditions and most of all how much energy their turbines would harvest over time.

“That’s considered their profit,” explains Kuester. “They use a virtual currency, scaled to give a more or less realistically final cost, to determine how their profit will offset design and manufacturing costs. They must determine, given the 30-year window that turbine has to last — and with the likelihood of an earthquake occurring every 10 years — how much money it takes to deploy their wind turbine.”

The teams are given standardized materials to construct their scaled turbines, which must include a support tower, but few other parameters are set in stone.

“The tubes they use for the support towers they can bend or shape however they want,” he adds, “but of course the more materials they use the more expensive the finished product will be. For the blade, we provide a maximum length but it’s up to the students to design the actual blade geometry most suitable for the existing wind characteristics at the target site”

It’s a labor-intensive process that ends in glory for the top three teams of student engineers. The class chooses their favorites (based on a pre-determined performance index) after two-day bonanza of wind tunnel, pushover and earthquake simulations on a shake table — with simulations based on actual earthquakes that have occurred in California, Chile and Japan. The students are responsible for the turbine’s final assembly process before testing begins and on-the-spot damage prediction and assessment. “From a power provider perspective, the end goal is the amount of energy produced over the given lifetime of the product," says Kuester. "From a structural engineering perspective, it’s about how well a design will withstand natural disasters such as earthquakes and the students will have to optimize for both”

|

Adds Porter: "We always try to provide as much 'hands on' experience as possible in our lab classes. I also believe that staging our engineering design lab courses as team competitions creates excitement and fosters innovation. Economics are always factored into the judging. Therefore the projects have a virtual cost that the teams must incur for producing a quality product (wind turbine — in this case) and then the opportunity to earn or generate income to offset these costs."

The students are also required to present their projects in front of their peers in the form of a sales pitch “to practice their communication skills,” says Kuester.

“By doing this they are also exposing themselves and their designs to each other,” he adds. “It puts the competition on notice. If you have good ideas, others will pick up on them, meaning that you will have to keep innovating no matter what.”

Kuester says the level of innovative thinking and engineering that this integrative design approach promoted was impressive. He reports that some teams went through more than dozen design iterations (previously students could do one, at most) before they felt confident their turbines would both withstand the simulated earthquake and give them an edge over the competition on power production capabilities.

“We want to make sure they understand the design challenges but also the real-life concerns,” he adds. “We want them to realize there’s value in really good design. Sometimes you get lucky, normally you don’t quite. Even if their next design is not as good, they learn something from it.”

Kuester says one of the things he appreciates most about teaching SE 120 is the enthusiasm the students have for building something tangible.

“They say, ‘I finally have something I can take to my parents and say, “This is what I’ve done, this is what I’ve learned.' It’s not just mathematics, it’s something they’ve thought about, designed, and actually produced at the end of the day.”

Adds Porter: "This is a third-year (Junior) class and for many of these students, by this point in time, I have had the privilege of working with them since their Freshman year. It is very rewarding to see them grow and mature in many ways.

"We like to change up the projects from time to time and introduce new challenges within the projects. We try to utilize the newest technologies and software. However it still always comes down to human creativity, innovation and ethics."

Media Contacts

Tiffany Fox

Qualcomm Institute

858-246-0353

tfox@ucsd.edu